Closed Circuit Cooling Towers

Sealed, efficient heat rejection systems – ideal for clean process cooling and reduced water contamination.

Read more

Overview ..

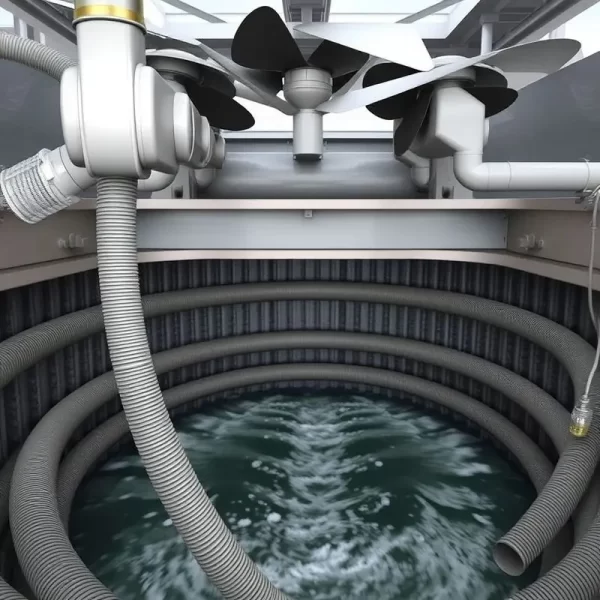

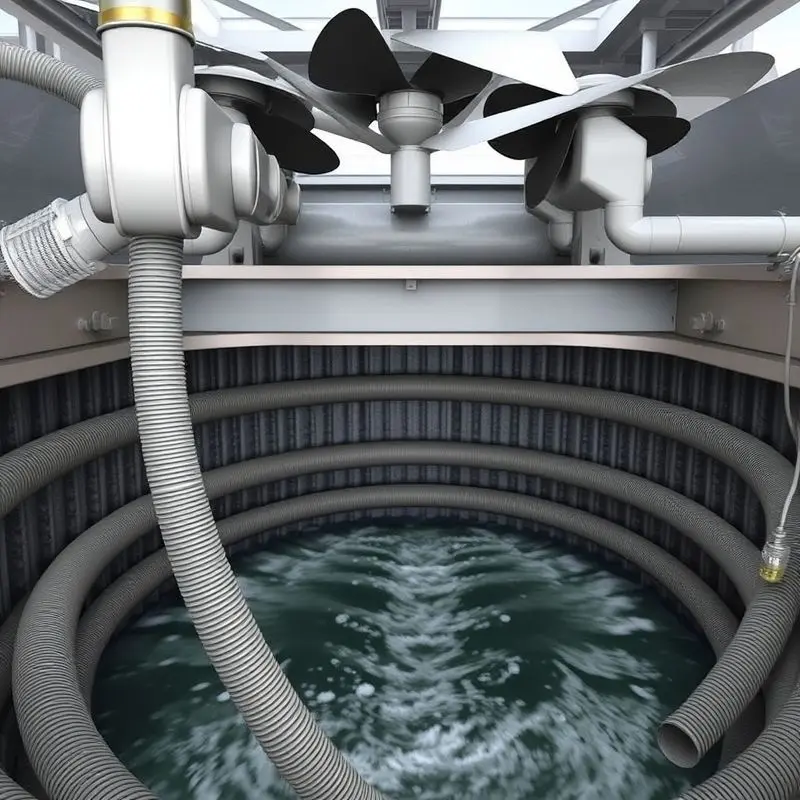

Four Air manufactures closed circuit cooling towers (also known as dry-wet coolers or fluid coolers) designed to deliver high-efficiency cooling without exposing the process fluid to outside air. This minimizes contamination, scaling, and system fouling — making it perfect for sensitive or closed-loop systems.

In these systems, heat is removed from process fluid via a heat exchange coil, over which water is sprayed and cooled by ambient airflow. The process fluid remains sealed within the coil, ensuring clean and efficient operation.

Overview ..

Four Air manufactures closed circuit cooling towers (also known as dry-wet coolers or fluid coolers) designed to deliver high-efficiency cooling without exposing the process fluid to outside air. This minimizes contamination, scaling, and system fouling — making it perfect for sensitive or closed-loop systems.

In these systems, heat is removed from process fluid via a heat exchange coil, over which water is sprayed and cooled by ambient airflow. The process fluid remains sealed within the coil, ensuring clean and efficient operation.

System Features

Technical Specifications

|

Specification |

Details |

|---|---|

|

Cooling Capacity |

50 TR – 3,000 TR |

|

Coil Material |

Copper / Stainless Steel |

|

Casing |

Epoxy-coated Galvanized Steel / Stainless |

|

Fan Type |

Axial / Centrifugal |

|

Operating Pressure |

Up to 10 bar |

|

Fill Type |

Film or Splash Fill |

|

Maintenance Access |

Easy-open panels for coil inspection |

|

Drift Loss |

≤ 0.001% |