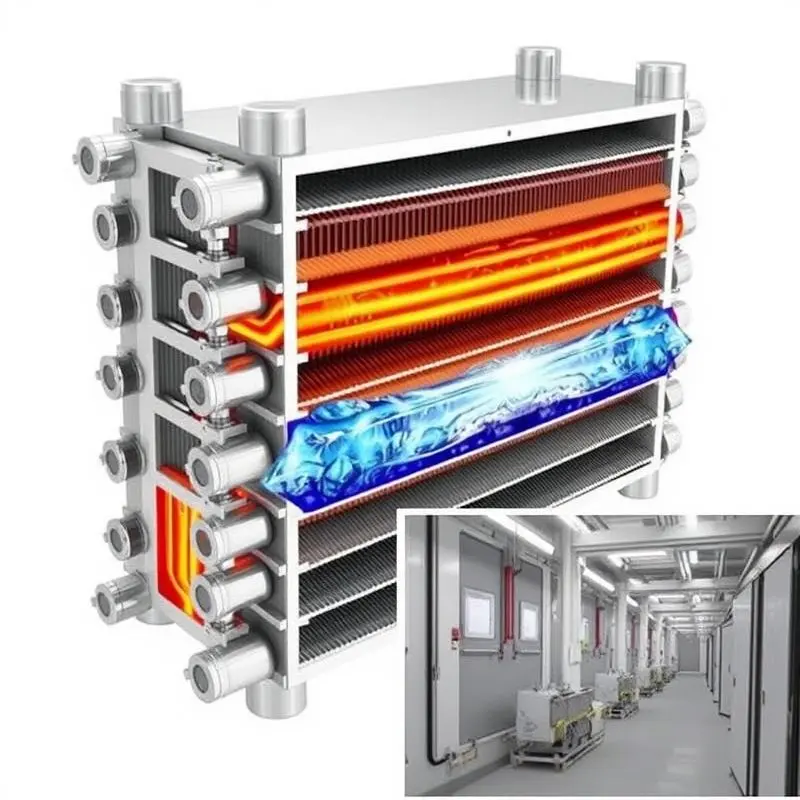

Plate Heat Exchangers – Compact, Efficient, and Customizable Thermal Transfer Solutions

Read more

Reliable Cooling Solutions for Diverse Industrial and Commercial Applications

Four Air designs and installs customized Freon (HFC-based) refrigeration systems, delivering reliable, energy-efficient cooling for cold storage, food processing, supermarkets, pharmaceuticals, and more.

Whether you're cooling water, heating glycol, or transferring energy between two process streams, our plate exchangers offer unbeatable performance and serviceability.

Whether used for cooling, heating, or condensing, our exchangers deliver unmatched reliability across a wide range of industries.

Our systems are compact, easy to install, and ideal for low to medium-capacity applications where ammonia isn’t suitable.

Key Product Features

Technical Specifications

|

Specification |

Details |

|---|---|

|

Plate Material |

SS 304 / SS 316 / Titanium / Hastelloy |

|

Gasket Type |

NBR / EPDM / Viton |

|

Max Pressure |

Up to 30 bar (Gasketed) / 45 bar (Brazed) |

|

Max Temperature |

Up to 200°C |

|

Flow Configuration |

Counter-flow / Co-flow / Multi-pass |

|

No. of Plates |

From 20 to 500+ |

|

Heat Transfer Area |

Customized (5 – 500 m²+) |

|

Connections |

Threaded / Flanged / Clamp-type |